Custom Block Neodymium Magnets with High Quality

Custom Block Neodymium Magnets with High Quality

Product dispaly

Product Information

| Product Name | Neodymium Magnet, NdFeB Magnet | |

| Material | Neodymium Iron Boron | |

| Grade & Working Temperature | Grade | Working Temperature |

| N30-N55 | +80℃ | |

| N30M-N52 | +100℃ | |

| N30H-N52H | +120℃ | |

| N30SH-N50SH | +150℃ | |

| N25UH-N50U | +180℃ | |

| N28EH-N48EH | +200℃ | |

| N28AH-N45AH | +220℃ | |

| Shape | Disc, Cylinder, Block, Ring, Countersunk, Segment, Trapezoid and Irregular shapes and more. Customized shapes are available | |

| Coating | Ni, Zn, Au, Ag, Epoxy, Passivated, etc.. | |

| Application | Sensors, motors, filter automobiles, magnetic holders, loudspeakers, wind generators, medical equipment, etc. | |

| Sample | If in stock, free sample and deliver at same day; Out of stock, delivery time is same with mass production | |

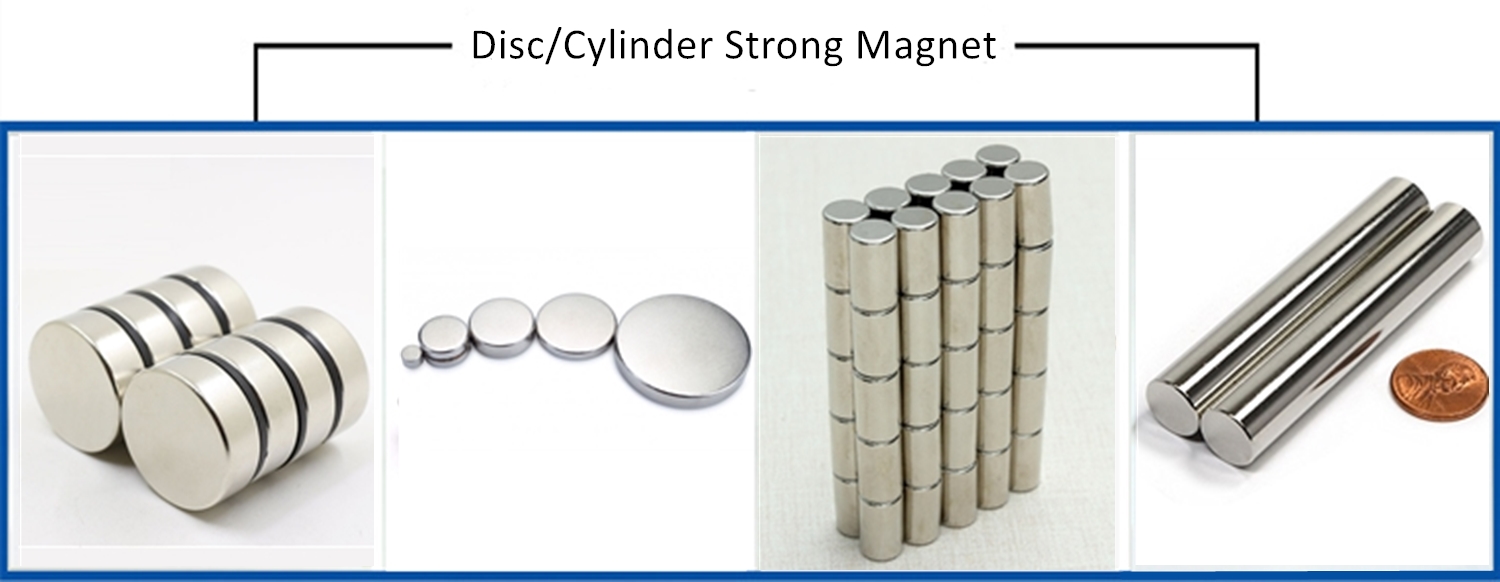

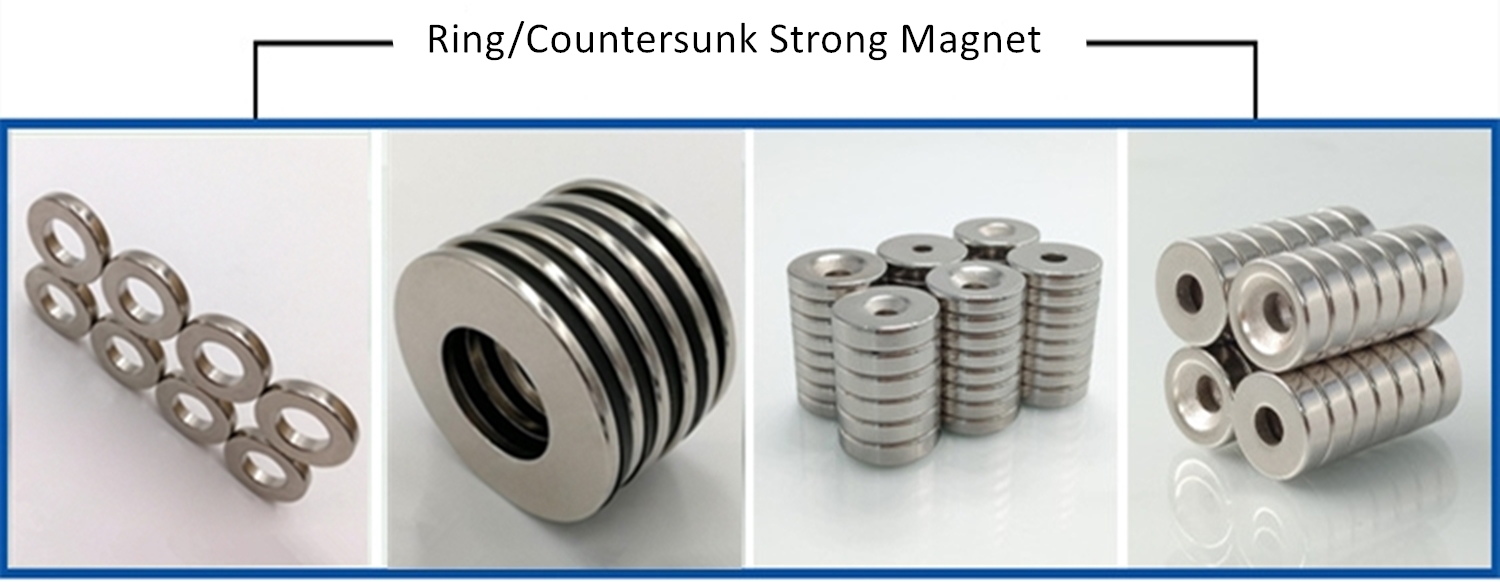

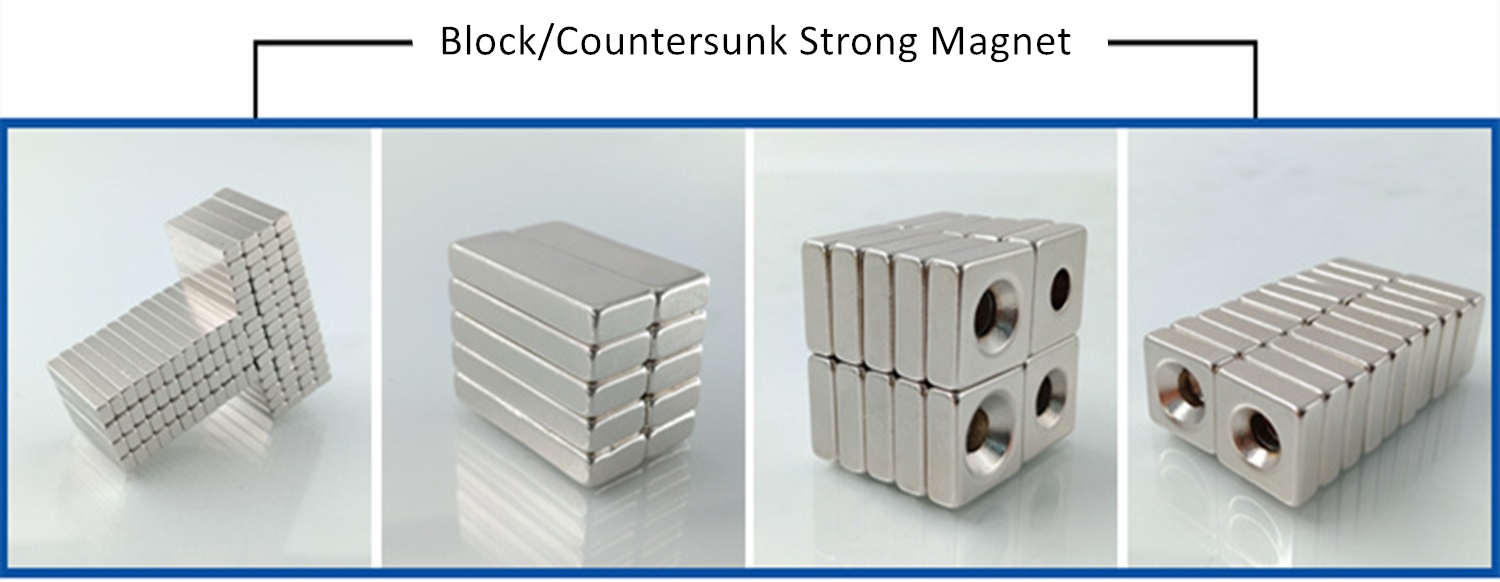

Magnets Display

Discs are round or cylindricalNeos and generally are identified by the diameter first then the height of the disc. So a magnet labeled as 0.500” x 0.125” is a 0.500” diameter by 0.125” tall disc. Unless specified otherwise, these magnets are magnetized through the thickness.

Rings are round Neos that have a hole in the center. These Neodymium magnets that are available for sale will require three dimensions, an outside diameter, and an inside diameter and thickness. Unless specified otherwise, these magnets are magnetized through the thickness.

Neo blocks are rectangular or square with a variety of size options. These will require three measurements: length, width, and thickness. Unless specified otherwise, these magnets are magnetized through the thickness.

Neo Arcs have various shapes with a variety of size options, it is better to have drawings to determine the details.

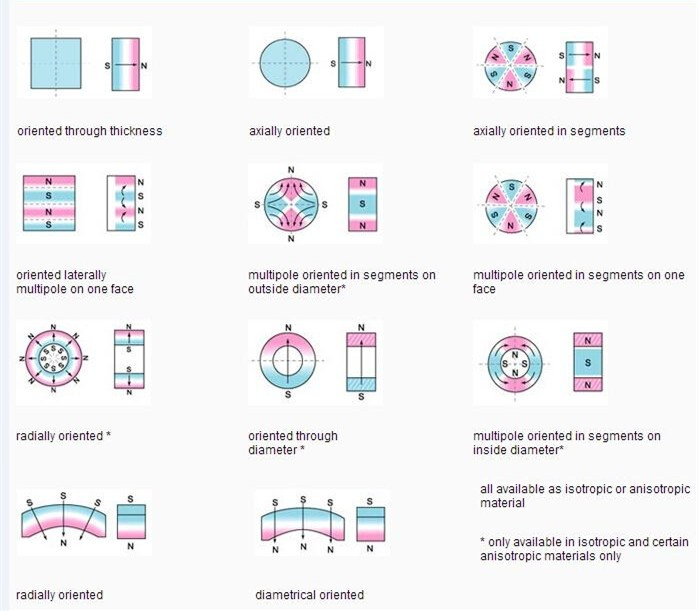

Magnetic Direction

Every magnet has a north seeking and a south seeking face on opposite ends. The north face of one magnet will always be attracted towards the south face of another magnet.

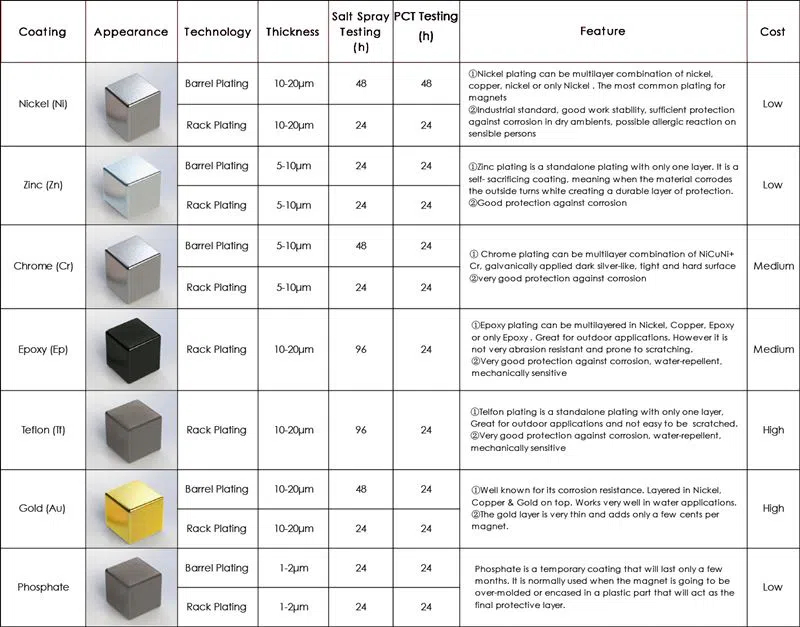

Coating

Support all magnet plating , like Ni, Zn, Epoxy , Gold, Silver etc.

Ni Plating Maget: The surface of stainless steel color, anti-oxidation effect is good, good appearance aloss, internal performance stability.

Zn Plating Magnet: Suitable for general requirements on surface appearance and oxidation resistance .

Epoxy Plating Magnet: Black surface, suitable for harsh atmospheric environment and hiqh requirements of corrosion protection ocasions

Application Fields

* Elevator motors

* Wind Power Generators

* Servo Motors

* Hybrid Electric Vehicle

* Linear Motors

* Compressor Motors

* Hydraulic Generators

* Other applications: Machinery, audio/video, and communication equipment, medical devices, office automation, magnetic separators, etc.

Our Strength

Neodymium Block Magnet Specification

1. High coercive force, strong magnetic power;

2. The maximum operation up to 230-degree centigrade;

3. Products manufactured according to ISO9001 quality system;

4. Coating: Ni, Ni-Cu-Ni, Zn, Ag, Au, and other special plating and coating;

5. Delivery time: 10-30days after confirming the order;

6. Payment terms: T/T, or Western Union;

7. We do our best to meet your request and make it fast to your hands.

Payment

Support: L/C, Westerm Union, D/P, D/A, T/T, MoneyGram, Credit Card, PayPal, etc..

Quote Is Fast & Easy

Whether your have custom specifications or are just looking for guidance, our experts help point you in the right direction. Simply call and we’ll review your specs and contact you with any questions. As always, we promise we will...

- Provide same day quotes, meet short lead times, and provide expedited delivery.

- Customize the job to meet your exact specifications.

- Deliver custom hard magnets in weeks, not months.

- Save you both time and money when you commit to Zhaobao Magnet.

Chat Now!

Vivian Xu

Sales Manager

Zhaobao Magnet Group

---30 years magnets manufacturer

Fixed Line:+86-551-87877118

Email: zb10@magnet-supplier.com

Mobile: Wechat/Whatsapp +86-18119606123

Address: Room 201, No. 15, Longxinli, Siming District,Xiamen,Fujian,China.

PRODUCT CATEGORIES

Focus on providing magnets solutions for 30 years