Factory Super Strong Big Neodymium N52 Disc Magnet 50×30 For Sale

Factory Super Strong Big Neodymium N52 Disc Magnet 50×30 For Sale

Overview

Permanent ferrite magnet, also known as hard magnet, is a non-metallic magnetic material.In 1930, Kato and Wujing discovered a kind of spinel (MgA12O4) permanent magnet, which is the prototype of ferrite widely used today.Ferrite magnet are mainly made of SrO or Bao and Fe2O3 as raw materials by ceramic process (pre firing, crushing, pulverizing, pressing, sintering and grinding). It has the characteristics of wide hysteresis loop, high coercive force and high remanence. It is a kind of functional material that can keep constant magnetism once magnetized. Its density is 4.8g/cm3. According to different production processes, ferrite magnet can be divided into two types: sintering and bonding. Sintering can be divided into dry pressing and wet pressing, and bonding can be divided into extrusion, compression and injection molding. The soft, elastic and twisted magnet made of bonded ferrite powder and synthetic rubber is also called rubber magnet. According to whether the external magnetic field is applied or not, it can be divided into isotropic permanent magnet and anisotropic permanent magnet.

Compare with other magnetic materials

Advantage: Low price, wide source of raw materials, high temperature resistance (up to 250 ℃) and corrosion resistance.

Disadvantage: Compared with NdFeB products, its remanence is very low. In addition, due to the relatively loose and fragile structure of its low density material, many processing methods are limited by it, such as punching, digging, etc., the majority of its product shape can only be pressed by the mold, the product tolerance accuracy is poor, and the mold cost is high.

Coating: Due to its excellent corrosion resistance, it does not need coating protection.

Product Feature

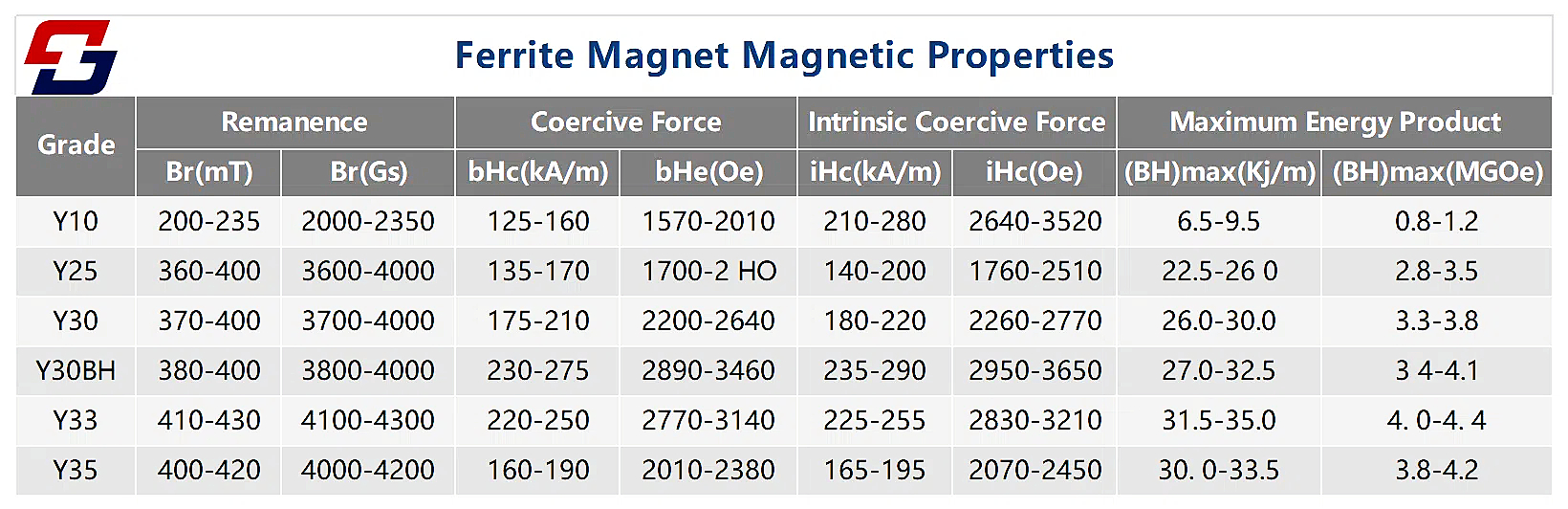

This is the performance table of our ferrite magnet

We can customize different kinds of shapes and dimensions ferrite magnets.

Certifications

Our company has passed a number of international authoritative quality and environmental system certifications, which is EN71/ROHS/REACH/ASTM/CPSIA/CHCC/CPSC/CA65/ISO and other authoritative certifications.

Why choose US?

(1) You can ensure product safety by selecting from us, we are reliable certified suppliers.

(2) Over 100 million magnets delivered to American, European, Asian and African countries.

(3) One stop service from R&D to mass production.

RFQ

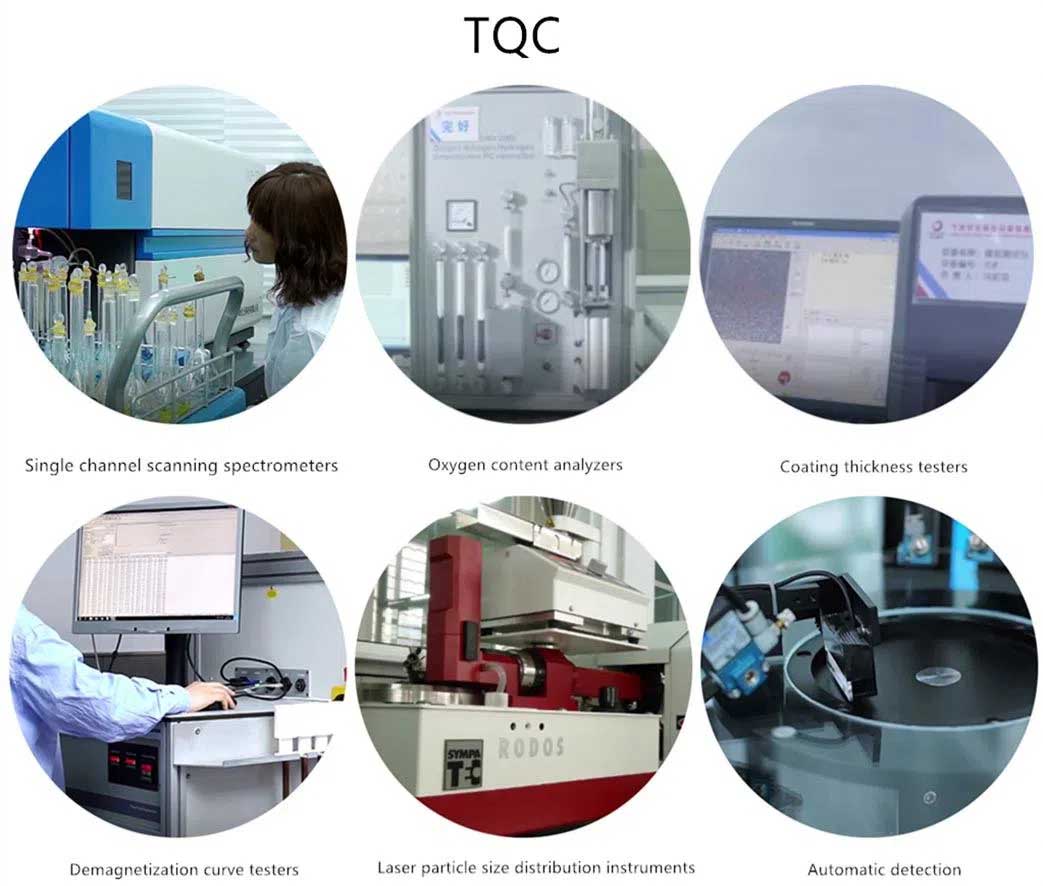

Q1:How do you control your quality?

A:We have advanced processing equipment and testing equipment, which can achieve strong control ability of product stablity, consistency and tolerance accuracy.

Q2: Can you offer the products customized size or shape?

A:Yes, the size and shape are based on coustomer's requierment.

Q3:How long is your lead time?

A:Generally it is 15~20 days and we can negotiate.

Delivery

1. If the inventory is enough, the delivery time is about 1-3 days. And the production time is about 10-15 days.

2.One-stop delivery service,door-to-door delivery or Amazon warehouse. Some countries or regions can provide DDP service, which means that we

will help you to clear customs and bear customs duties, this means you don't have to pay any other cost.

3. Support express, air, sea, train, truck etc. and DDP, DDU, CIF, FOB, EXW trade term.

Payment

Support: L/C, Westerm Union, D/P, D/A, T/T, MoneyGram, Credit Card, PayPal, etc..

PRODUCT CATEGORIES

Focus on providing magnets solutions for 30 years