30 years factory wholesale strong magnets n52 neodymium magnets

30 years factory wholesale strong magnets n52 neodymium magnets

Product Information

| Product Name | Neodymium Magnet, NdFeB Magnet | |

| Material | Neodymium Iron Boron | |

| Grade & Working Temperature | Grade | Working Temperature |

| N30-N55 | +80℃ | |

| N30M-N52 | +100℃ | |

| N30H-N52H | +120℃ | |

| N30SH-N50SH | +150℃ | |

| N25UH-N50U | +180℃ | |

| N28EH-N48EH | +200℃ | |

| N28AH-N45AH | +220℃ | |

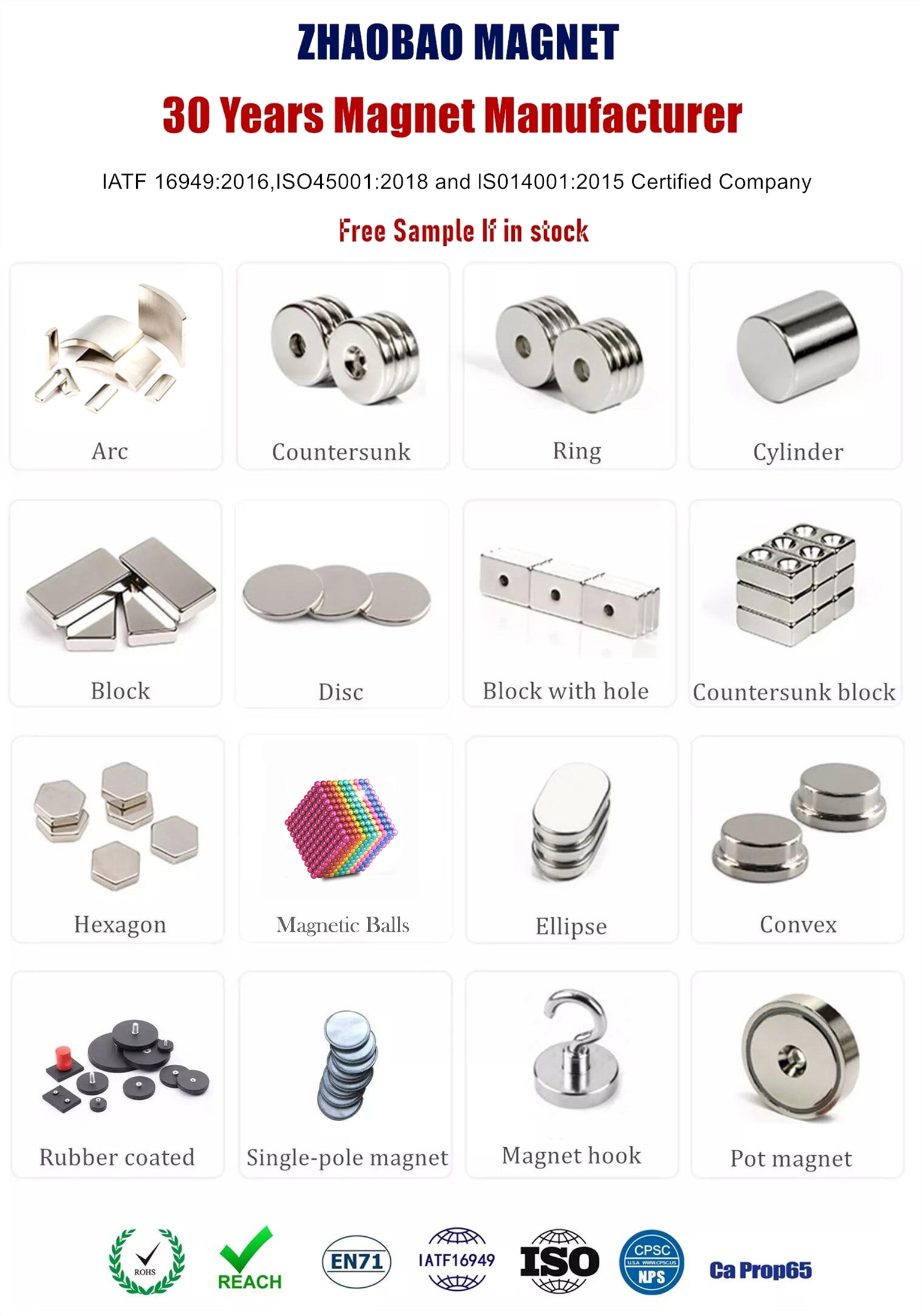

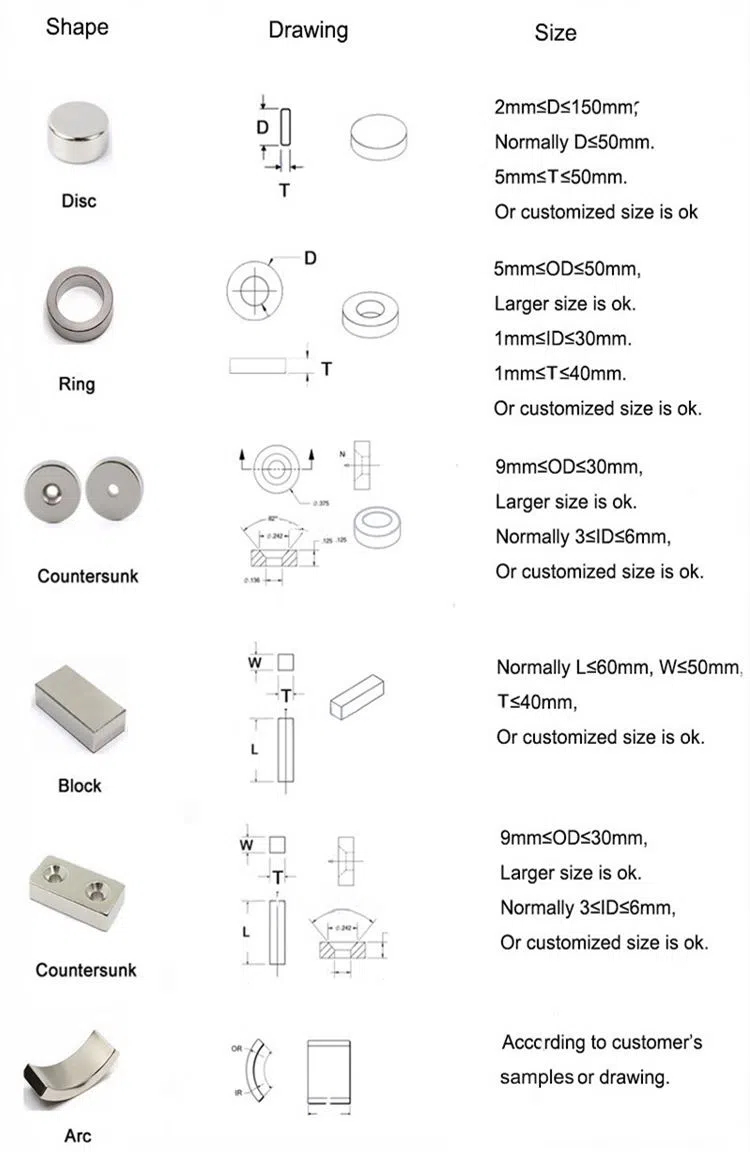

| Shape | Disc, Cylinder, Block, Ring, Countersunk, Segment, Trapezoid and Irregular shapes and more. Customized shapes are available | |

| Coating | Ni, Zn, Au, Ag, Epoxy, Passivated, etc.. | |

| Application | Sensors, motors, filter automobiles, magnetic holders, loudspeakers, wind generators, medical equipment, etc. | |

| Sample | If in stock, free sample and deliver at same day; Out of stock, delivery time is same with mass production | |

Product dispaly

Customized neodymium magnets

Disc neodymium magnet, size and grade can be customized

The grade can be N28-N52. Magnetic direction, coating material and size can be customized according clients' request

Block neodymium magnet, , size and grade can be customized

The grade can be N28-N52. Magnetic direction, coating material and size can be customized according clients' request

Ring neodymium magnet, size and grade can be customized

The grade can be N28-N52. Magnetic direction, coating material and size can be customized according clients' request

Arc neodymium magnet, size and grade can be customized, temperature resistance up to 220℃ for some special motor use

The grade can be N28-N52. Magnetic direction, coating material and size can be customized according clients' request. Some special request of temperature resistance also can be satisfied, we customize high temperature resistance magnets up to 220℃

Countersink neodymium magnet of different shapes

The grade can be N28-N52. Magnetic direction, coating material and size can be customized according clients' request

Special shape neodymium magnets, shape, size and grade can be customized

The grade can be N28-N52. Magnetic direction, coating material and size can be customized according clients' request. Compared with other manufacturer, except normal shapes, we also good at making different kinds of special shape magnets

Shapes and sizes

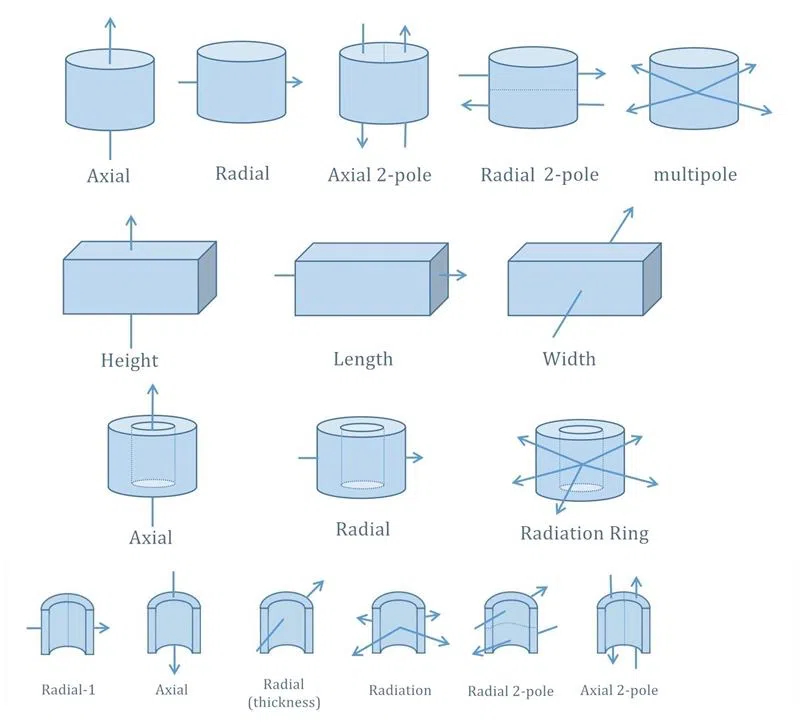

Magnetic Direction

The magnetization direction of the magnet has been determined during pressing. The magnetization direction of the finished product cannot be changed. Please be sure to confirm the required magnetization direction

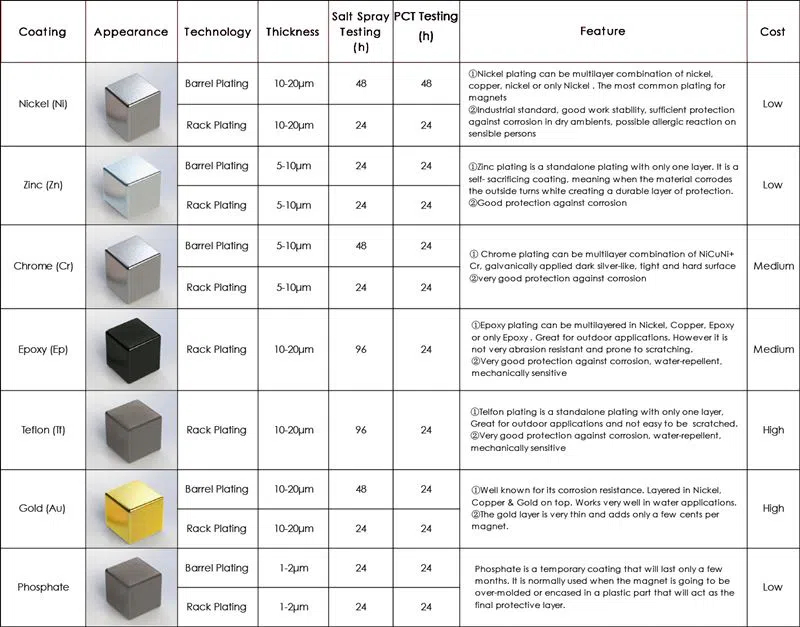

Coating

There are many different coating and plating options for neodymium magnets. The most common coating for neodymium magnets is a nickel plating. While commonly referred to as simply “nickel plating,” this nickel option is actually a three layer plating that comprises of a nickel layer, a copper layer, and a nickel coating. Some other options for coating are zinc, tin, copper, epoxy,silver and gold.

Advantage

- Over 30 Years OEM Manufacturing Experience: Produce magnetic products.

- Accept Sample order/Low MOQ trial order.With High Quality and Competitive Price.

- For your inquiry we will reply you within 24 hours.Professional Sales will solve your question.

- Neodymium Permanent Magnet is customized, the grade we could produce is N35-N52(M,H,SH,UH,EH,AH), for the grade and shape of the Magnet, if you need, we could send you the catalogue. If you need technical support about the Permanent Magnet and Neodymium Permanent Magnet Assemblies, we could give you the biggest support.

- After sending, we will track the products for you once every two days, until you get the products. When you got the goods, test them, and give me a feedback.If you have any questions about the problem, contact with us, we will offer the solve way for you.

Why choose US?

FAQ

Q1:Are you a manufactuer or trading company?

A:We are 30 years permanent magnet manufacturer, and we welcome you to visit our factory

Q2:Can you do the design for us?

A:Yes,we can. We have the most professional technical team to provide customized services for you. Size, performance, coating etc.

Q3:What's the MOQ for your production?

A:There are different MOQs according to the size and performance of the products. Please contact the customer service personnel for details.

Q4:How do you control your quality?

A:We have advanced processing equipment and testing equipment, which can achieve strong control ability of product stablity, consistency and tolerance accuracy.

Q5: Can you offer the products customized size or shape?

A:Yes, the size and shape are based on coustomer's requierment.

Q6:How long is your lead time?

A:Generally it is 15~20 days and we can negotiate.

Delivery

We support express, air, sea, train, truck etc. and DDP, DDU, CIF, FOB, EXW trade term.One-stop delivery service,door-to-door delivery or Amazon warehouse. Some countries or regions can provide DDP service, which means that we will help you to clear customs and bear customs duties, this means you don't have to pay any other cost.

Payment

Support: L/C, Westerm Union, D/P, D/A, T/T, MoneyGram, Credit Card, PayPal, etc..

Chat now!

Zora LingSales ManagerZhaobao Magnet Group---30 years magnets manufacturerFixed Line:+86-551-87878228Email: zb22@magnet-supplier.com

Mobile: Wechat/Whatsapp +86-18134522123Address: Room 201, No. 15, Longxinli, Siming District,Xiamen,Fujian,China.

PRODUCT CATEGORIES

Focus on providing magnets solutions for 30 years